Your product configurator

- News

- Events

- Csr

- Welfare

2025-11-12

2025-11-10

2025-10-30

2025-10-29

CUSTOMER REVIEWS

The exchange with the various departments is always very stimulating, efficient, and problem-solving oriented. The contact persons are all experts in their field. They are polite, reliable, and dependable across the board.

We’re happy to work closely with VIS as a long-term partner. All colleagues understand and care for our requests with a professional approach. It’s an honor for us to carry their brand together with quality products in hydraulic systems that we manufacture.

A very professional and friendly company. They always try their best to accommodate any urgent demand and at disposal for any kind of advice, to reach a positive outcome. Glad to work with truly passionate suppliers that care about their products and look after their customers.

Very pleased with the collaboration with VIS; they’re solution oriented and quick to respond, always willing to help. They provide good informations and everything is made in the correct way; order confirmations, invoices, delivery and packaging.

VIS is a long-term partner for Bucher worldwide. Quality, service and collaboration are common values founding a trusty relationship.

The essence of Italian technology transformed into competitive and innovative products. Passion, competence, sharp vision future on hydraulics industry, combined with great attention to sustainability and human relationship, make VIS an outstanding reality in our field.

INNOVATION CENTER

Innovation Center represents the blend of our desire to innovate with the strong experience on products and processes built in these years of development.

Our aim is to support our customers in any stage of development for their projects from design to validation and final approval.

Innovation Center inter-dept. structure supplies high-level technical and quality services with the fast response and the flexibility that distinguish us.

COMPANY VIDEO

FEATURED PRODUCTS

PCD0 .S10 Proportional Solenoid Valves - Cartridge Style

The PCD0 is a proportional solenoid operated, direct acting, poppet type, two way, screw-in hydraulic cartridge normally closed pressure compensated flow regulator. When de-energized the flow is fully restricted. When energized the regulated flow is proportional to the applied control current. The regulated flow rate is independent of the pressure differential between the ports.

All External surfaces are zinc plated and corrosion proof. All valve parts are made of high strength steel. Efficient wet armature design.Industry standard SAE cavity.

Maximum operating pressure

250 bar

Maximum flow

30 l/min

Maximum internal leakage

20 cm3/min @ 30 bar 150 cm3/min @ 250 bar

Pressure Compensation Range

30 - 250 bar

External component treatment

Zn/Fe - standard (96h)ZN/Ni (720h) - Upon customer request

O-ring temperature range

-30 ° C to 110 ° C (standard sealing NBR - BUNA - N)-25 ° C to 140 ° C - HNBR - Upon customer request-23 ° C to 225 ° C - FKM - Upon customer request

Oil temperature range

-30 ° C to 110 ° C

Fluids

Mineral - based or synthetics with lubricating properties

Viscosities

7,4 to 420 cSt

Filtration

20 / 18 / 15 ISO 4406 (maximum filtration admitted)

Orientation

No restrictions

Installation torque

35 - 40 Nm Hex 24

Oil testing condition

ISO VG 46 cSt

Seal Kit

SK.032 and SK.087 (coil)

Coil

26 W Performance and Validation test performed with VIS products CCR1D.C12.L0 (12Vdc-26W) and CCR1D.C24.L0 (24Vdc-26W)

Weight

0,210 Kg

LSD0 .S10 Pressure Compensator - Cartridge Style

A cartrdige style, screw-in, spool type, normally closed, hydraulic directional element. An orifice through the spool connects port 1 to port 3, which allows remote control of the valve by connecting port 3 to a pressure control or a solenoid valve. The flow from 1 to 2 is allowed only when 3 is vented to create a pressure drop across the internal orifice which exceeds the pressure value of the selected bias spring force. These valves can be used as unloading valves or in pressure control and bypass circuits. Available version with cleaning wire to preserve cleanliness of the orifice.

External surfaces are zinc plated and corrosion-protected. All valve parts are made of high strength steel. Spool is hardened and ground to guarantee low wear and to extend service life. Suitable for heavy duty applications. Compact size. Industry SAE common cavity. NOTE: This product is not intended to be used for man lifting applications with the purpose to limit the lowering speed.

Maximum operating pressure

350 bar

Maximum flow

80 l/min

Maximum internal leakage

50 cm3/min @ 200 bar

External component treatment

Zn/Fe - standard (96h)Zn/Ni (720h) - Upon customer request

O-ring temperature range

-30 ° C to 110 ° C (standard sealing NBR - BUNA - N)-35 ° C to 140 ° C - HNBR - Upon customer request-23 ° C to 225 ° C - FKM - Upon customer request

Oil temperature range

-30 ° C to 110 ° C

Fluids

Mineral - based or synthetics with lubricating properties

Viscosities

7,4 to 420 cSt

Filtration

20 / 18 / 15 ISO 4406 (maximum filtration admitted)

Orientation

No restrictions

Installation torque

50 - 55 Nm Hex 27

Oil testing condition

ISO VG 46 cSt

Seal Kit

SK.124

Weight

0,137 Kg

FRP* .S10 Flow Controls - Cartridge Style

A screw-in, cartridge style, direct acting, 3-way pressure compensated flow control valve. The flow rate of this valve in the 1 to 3 flow path is largely independent of the system pressure or in the the bypass-way and is determined by the dimension of a calibrated orifice. The FRP0.S10 is a priority type regulator, delivering the pump flow to port 3 first, then bypassing excess to port 2. All ports may be fully pressurized. Flow out of priority port 3 may vary based on input flow amount, particularly with lower temperatures and increased fluid viscosities. The valve cannot be adjusted for variable flow output. Free flow in the 2 to 1 path is allowed and not pressure compensated.

External surfaces are zinc plated and corrosion-protected. All valve parts are made of high strength steel. Spool is hardened and ground to guarantee low wear and to extend service life. Optional: upon request a calibrated steel wire can be installed inside the spring chamber in order to prevent possible orifice obstruction. Suitable for heavy duty applications. Compact size. Industry SAE common cavity. NOTE: This product is not intended to be used for man lifting applications with the purpose to limit the lowering speed.

Maximum operating pressure

350 bar

Maximum flow

60 l/min

Maximum internal leakage

cm3/min @ bar

External component treatment

Zn/Fe - Standard (96h)Zn/Ni (720h) - Upon customer request

O-ring temperature range

-30 ° C to 110 ° C (standard sealing NBR - BUNA - N)-35 ° C to 140 ° C - HNBR - Upon customer request-23 ° C to 225 ° C - FKM - Upon customer request

Oil temperature range

-30 ° C to 110 ° C

Fluids

Mineral - based or synthetics with lubricating properties

Viscosities

7,4 to 420 cSt

Filtration

20 / 18 / 15 ISO 4406 (maximum filtration admitted)

Orientation

No restrictions

Installation torque

50 - 55 Nm Hex 1"

Oil testing condition

ISO VG 46 cSt

Seal Kit

SK.049

Weight

0,143 Kg

LSC0 .S10 Pressure Compensator - Cartridge Style

A cartridge style, screw-in. When pressure at 1 rises above the selected spring bias pressure against the spool, the valve shifts to allow flow from 1 to 2. Pilot pressure at 3 is additive to the spring bias pressure. The valve may be used in switching or compensation type applications.

All external surfaces are zinc plated and corrosion- proof. All valve parts are made of high strength steel. Compact size. Industry SAE common cavity.

Maximum operating pressure

350 bar

Maximum flow

80 l/min

Maximum internal leakage

50 cm3/min @ 200 bar

External component treatment

Zn/Fe - standard (96h)Zn/Ni (720h) - Upon customer request

O-ring temperature range

-30 ° C to 110 ° C (standard sealing NBR - BUNA - N)-35 ° C to 140 ° C - HNBR - Upon customer request-23 ° C to 225 ° C - FKM - Upon customer request

Oil temperature range

-30 ° C to 110 ° C

Fluids

Mineral - based or synthetics with lubricating properties

Viscosities

7,4 to 420 cSt

Filtration

20 / 18 / 15 ISO 4406 (maximum filtration admitted)

Orientation

No restrictions

Installation torque

50 - 55 Nm Hex 27

Oil testing condition

ISO VG 46 cSt

Seal Kit

SK.124

Weight

0,142 Kg

OUR CARE FOR CUSTOMERS

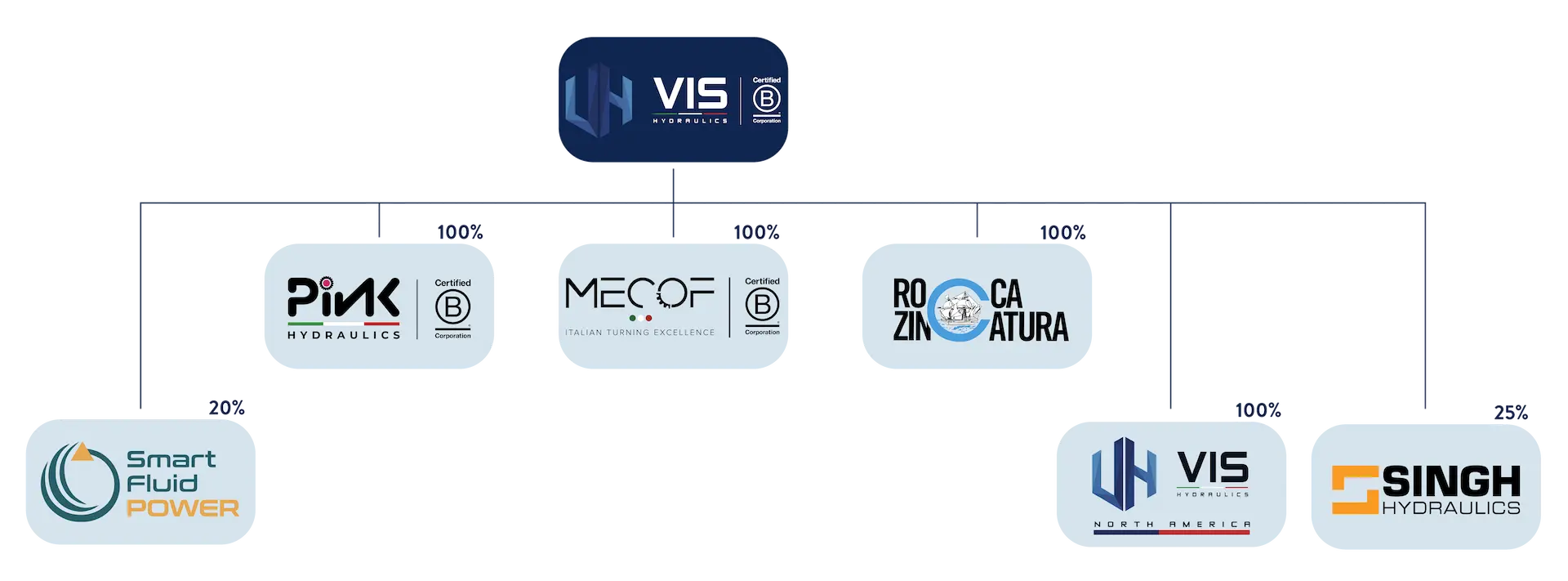

OUR CORPORATE STRUCTURE

WE PROUDLY SUPPORT